The sugar industry is the second largest agriculture-based industry after textiles and Pakistan ranked 15th in the world in sugarcane production. Pakistan’s sugarcane crushing capacity has grown rapidly over the last decade, however difficult pricing conditions and the financial crisis due to political/social/climatic factors forced sugarcane mills to invest less.

The sugar industry has been facing a situation quite similar to the textile industry stemming out of unchecked growth of the sector because of project sanctioning on political grounds without any consideration to raw material availability and market size.

The problem is more intense for the newer units, which have a lower crushing capacity and higher associated financial costs. Currently, approximately 78 industrial players share the sugarcane industry in Pakistan with crushing capacity of 365,000 TCD (tons crushed per day).

Sugarcane is a unique multi-year crop, which can be harvested annually up to 6-7 years without replanting. After an annual harvest, the roots and lower parts of the plant remaining in the field, the ratoons, grow new stems that are cut the following year. On most farms, sugarcane is harvested continuously over 9 months. Importantly, this allows crushing to be continuous.

Therefore, managing the harvesting and crushing occurs almost daily. Such high throughput production creates a tremendous need to provide regular crop yield estimates. Adding complexity, the daily harvest of cut sugarcane must be efficiently transported to a sugar mill for processing.

To ensure that the cut sugarcane is processed as quickly as possible and that the mills have a continuous supply, most sugar mills surround themselves with sugarcane farms for which they coordinate operations. Each sugar mill critically needs information about sugarcane production to manage and allocate their resources.

Existing methods to estimate crop yield

Sugarcane crop yield forecasting is a multi-billion-rupee business in our country. In addition to sugar mills, there are other stakeholders across the agricultural value chain, who are interested in understanding and forecasting the supply side of the sugarcane market.

These include commodities traders, banks and insurance companies, ethanol producers, sugarcane refineries, and large industrial sugarcane growers themselves. The efficient management of the harvesting and crushing processes help to increase the profitability in this sector, where prices should be controlled by the government.

Therefore, crop yield forecasting has a direct impact on the bottom line of a sugar mill. How do sugar mills accurately and reliably estimate sugar and biomass yield in Pakistan and worldwide? Sugar mills have been using different methodologies to estimate sugarcane crop yield since the beginning of commercial cultivation.

The most traditional ways to crop yield forecasting are manual scouting and crop sampling. One industrial farm might employ 100-200 field workers to scout and sample sugarcane fields in peak season. Scouting and sampling are inefficient, time-consuming, expensive, and highly dependent on the experience of field workers and agronomists.

Additionally, these methods produce incomplete observations, mature sugarcane can be 5-6 meters tall and densely planted, impeding workers from walking through the fields. Unfortunately, these constraints lead to inaccurate assessments of crop biomass and yield.

Another way to make a sugarcane crop yield prediction is to leverage (Normalized Difference Vegetation Index) NDVI-based methods. NDVI-based methods are relatively new and whereas they address some of the concerns of scouting and sampling, suffer from reduced reliability, accuracy, and scalability.

Changing climatic conditions, soil types, varieties and farming practices make it extremely difficult to estimate, accurately, yield for sugarcane over very large areas. Some research suggests that the relationship between NDVI-based metrics and its yield has R squared values of 0.48-0.53, concluding that “due to limitations associated with NDVI, additional plant indices evaluation would be beneficial”.

Most NDVI-based methods use multispectral imaging technology, which has a number of limitations, such as not being able to account for the diversity of the crop, soil and climatic conditions.

Sugarcane yield prediction through scientific approach

At Agro-Climatology Lab, University of Agriculture-Faisalabad, young scientists are working on how to provide accurate, reliable, and scalable biomass and yield estimates for the sugarcane market in Pakistan. Yield prediction is a function of biomass, growth stage, nitrogen uptake, precipitation, variety potential, soil type, etc.

The only way to address and account for the diversity of sugarcane varieties, soil, climate and farming practices is to build comprehensive, dynamic crop models, that simulate the growth of its plants throughout the crop season based on multiple variables.

The growth development cycle is divided into four phases, based on the its physiology. Data fed into these crop models include remote sensing, meteorology, agronomy, among other supplementary data. Remote sensing, and particularly hyperspectral imaging, offers a unique and efficient way to obtain spectral information in relation to the biophysical characteristics of the crop.

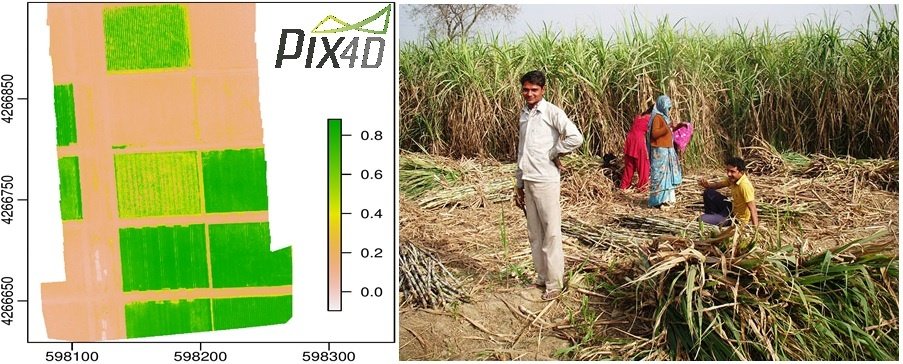

This relation between spectral information and crop biophysical characteristics helps to assess crop growth, chlorophyll content, biomass and yield. Crop yield prediction maps for different crops developed at Agro-Climatology Lab are important to expand scientist approach in prediction of sugarcane yield and pair with detailed statistics about different levels of biomass (kg/ha) in the field that can be helpful in policy making.

All fields can be compared, analyzed and prioritized for specific agronomic operations. Scientists at Agro-Climatology Lab are working to develop own processed based model to offers a unique and efficient way for accurately and reliably forecast of sugarcane biomass and yield throughout the full growing season and also to estimate area under cultivation that can rapidly equips sugar mills with essential information to make key decisions about its harvesting and crushing.

This can help mill operators to manage their logistics (opening dates, inputs, distribution of harvesting machines, etc.) and allocate resources (labor, machinery, etc.) according to the yield forecasts. Furthermore, this can help in optimization of harvesting based on maturity; growth monitoring throughout the season to better plan on-field operations; and biomass prediction to maximize yield output.

This article is jointly written by By Dr. Muhammad Naveed Arshad1,2, Prof. Dr. Ashfaq Ahmad1, Dr. Fahd Rasul1. The authors are associated with 1Agro-Climatology Lab, University of Agriculture, Faisalabad-Pakistan and 2University of California, Davis, USA. Correspondence author can be reached at naveedarshad26@gmail.com