The demonstration project will be funded in part by AUD 20.9 million from ARENA, as well as AUD 3 million from Queensland government-owned electricity provider Stanwell Corp.

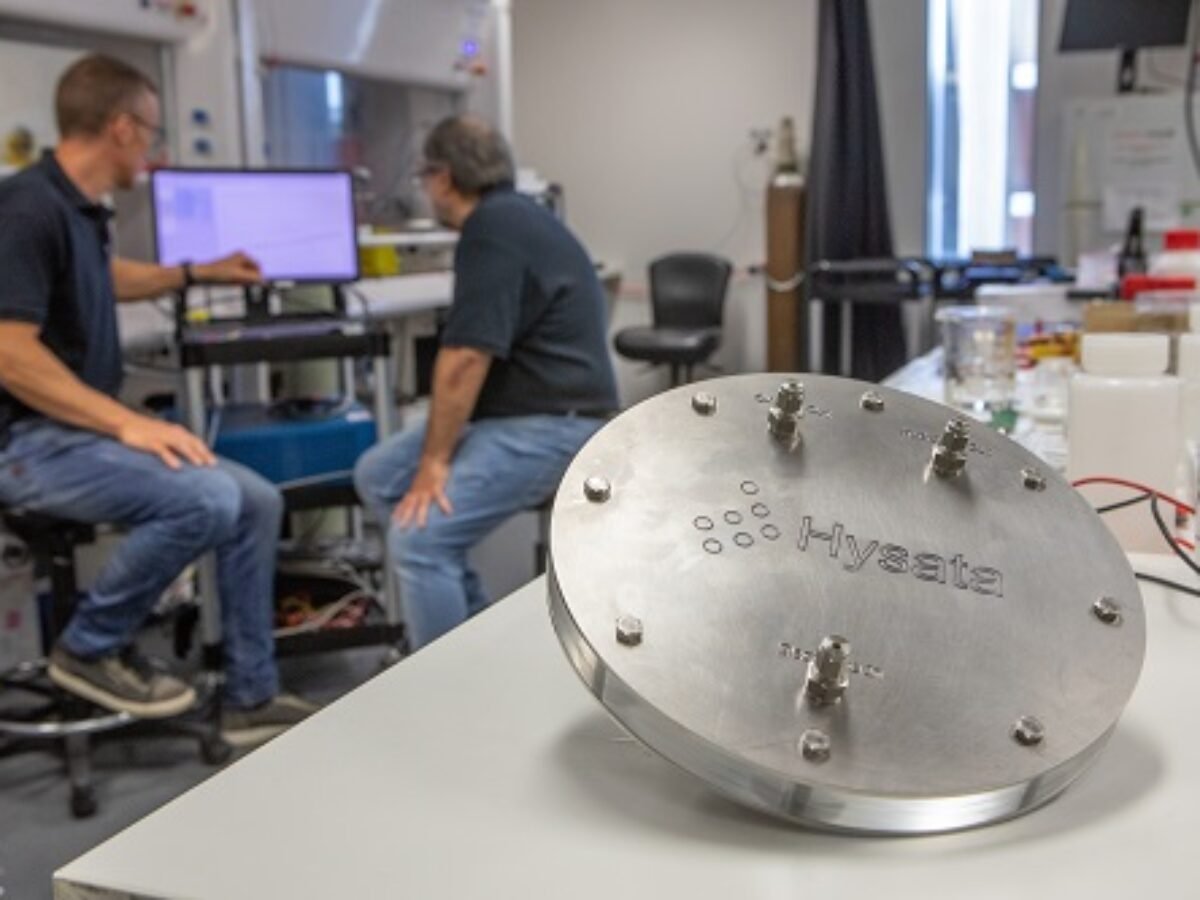

A project to quicken the development and commercialization of Hysata’s “capillary-fed” electrolyzer cell technology will be funded with more than AUD 23 million ($14.87 million) from the Australian and Queensland governments. Hysata is a company that was spun out from the University of Wollongong (UOW).

The demonstration project will be funded in part by AUD 20.9 million from the Australian Renewable Energy Agency (ARENA), as well as AUD 3 million from Queensland government-owned electricity provider Stanwell Corp. Additionally, Stanwell will supply the location and infrastructure needed for the electrolyser’s field deployment.

The ultra-high efficiency hydrogen electrolyzer technology being developed by Hysata almost removes all electrolysis resistance and has the potential to drastically alter the economics of producing green hydrogen.

Existing electrolyzers have energy losses due to electrical resistance and gas bubbles that develop on electrodes, which lowers the system’s overall efficiency, according to Hysata. In comparison to current technologies, which operate with efficiencies of about 75% (52.5 kWh/kg), [the technique] has been demonstrated to manufacture hydrogen with a 95% (41.5 kWh/kg) efficiency.

The method, according to ARENA, “has the potential to lower the cost of renewable hydrogen generation through reduced power inputs… With less electrical resistance, there are fewer cooling needs, which results in lower overall plant expenses. These decreased input costs, if implemented at scale, will assist in lowering the levelized cost of hydrogen, turning renewable hydrogen into a marketable energy source.

At its new electrolyzer production site in Port, Hysata intends to create and test a 5 MW unit.

New South Wales’ Kembla. The electrolyzer array will then undergo testing and validation before it is relocated to Queensland where it will be installed adjacent to the 1,460 MW Stanwell Power Station near Rockhampton. The site has available land, water and grid connection capacity.

According to Hysata company, the system’s preliminary development is currently under progress, and the field pilot at Stanwell is scheduled to start in 2025. As the business strives to complete a 9.4 GW pipeline of signed conditional orders and letters of intent, Hysata Chief Executive Officer Paul Barrett said the project represents a critical phase in its rapid technological and commercial growth.

“Our plan calls for the development of a 100 MW manufacturing line, the delivery of commercial-scale units, including the 5 MW electrolyzer unit for Stanwell’s project, in 2025. After that, we’ll quickly ramp up to giga-scale capacity, he added.

The research, according to ARENA Chief Executive Officer Darren Miller, is essential to authorizing purchase orders for the technology.

According to Miller, this electrolyser technique might revolutionize the production of renewable hydrogen. By demonstrating that the technology is practical at a large scale, the demonstration at Stanwell’s plant will be crucial to generating commercial demand for Hysata’s product.

The additional financing adds to the AUD 8.98 million already provided by ARENA under the German-Australian HyGATE initiative, together with an additional AUD 9 million from the Federal Ministry of Education and Research (BMBF) of Germany.

A 200 kW electrolyzer system that will showcase the essential elements of the 5 MW commercial-scale demonstration unit is being developed by Hysata with assistance from the HyGATE grant.