Researchers at the Lawrence Berkeley National Laboratory are creating fiber-optic cable-based sensing systems that will be mounted on FOSW structures off the coast of California.

One of the most promising clean energy technologies, floating offshore wind turbines (FOSW), have a potential market worth close to $16 billion. In deep water, where the winds are stronger and they can harvest more than twice as much energy, they must be moored to the seabed. To lower the cost of developing, deploying, and maintaining these complex systems, science and technology solutions are required.

Researchers at the Lawrence Berkeley National Laboratory are creating fiber-optic cable-based sensing systems that will be mounted on FOSW structures off the coast of California. This would enable structures to detect harmful conditions on their own and gauge the effects of FOSW on marine mammals.

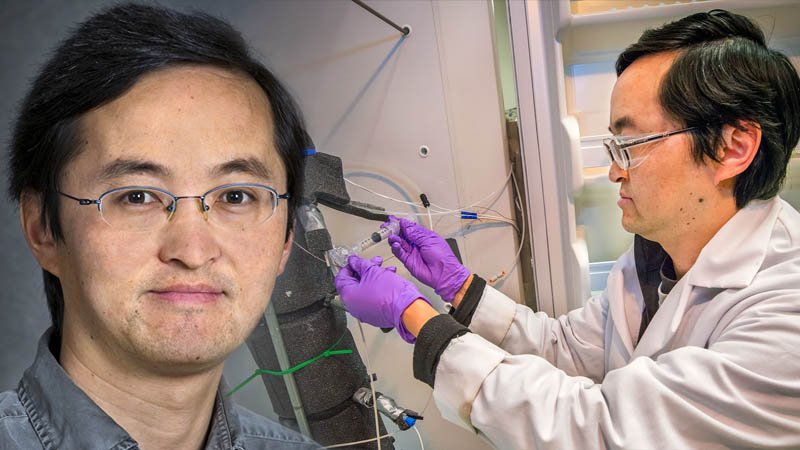

Yuxin Wu, a Berkeley Lab scientist, is working on solutions to lower the cost of FOSW development and deployment while reducing potential environmental impacts in conjunction with specialists in materials science, engineering, geophysics, and development of FOSW from around the world.

Q. What is the biggest obstacle to expanding floating offshore wind technologies?

Wu: So far, there have been few FOSW deployments because the technology is in the early stages of development. Currently, no such systems have been deployed anywhere near 1000 meters in depth.

We want to leverage scientific innovation by co-designing structural materials that are better able to withstand harsh marine environments and extreme weather events.

And we want to add distributed fiber optic sensing to FOSW systems to enable systems to self monitor in real time for potential problems, a capability that could prolong a system’s lifespan and lower operating and maintenance costs.

Q. How does your team apply fiber-optic sensing to these innovations?

Wu: A fiber cable has a glass core that allows you to send an optical signal at the speed of light; when there is any vibration, strains, or changes in temperature of the material that is being monitored, that information will be carried in the light signal that is scattered back.

When attached to or embedded within the wind turbine structure, this gives it a “nervous system” which allows it to “hear” and “feel.” The fiber is able to monitor surrounding acoustic signals, such as whale calls, which can help scientists monitor potential impacts to large marine mammals from FOSW operations.

We’ve been testing the deployment of this sensing technology to structural components – such as towers and turbines – to monitor physical and mechanical conditions experienced by the structure itself, like temperature or strain. Our research so far has focused on testing fiber optics on the tower and gearbox, some of the most expensive components where there is benefit to identifying damage before it leads to problems.

Q. How important is materials science to reducing the cost of floating offshore wind systems?

Wu: By revealing what is happening within a FOSW system in real time, fiber-optic sensing gives us the knowledge needed to develop more resilient, cost-effective materials at the system level.

Designing FOSW systems at lower cost and to withstand harsh marine environments requires cutting-edge materials science combined with computing science to produce better materials and to effectively simulate how the materials perform.

Materials can be developed to give the structures self-healing capabilities; for example, seawater intruding into a crack in concrete triggers reactions to seal the crack without interventions.

We are partnering with experts in materials science and simulations from the molecular to structural scale to bring about innovations that have great potential for future deep-water floating systems because of their large cost-saving potential, local producibility, better performance, and environmental sustainability.

DOE Office of Science user facilities at Berkeley Lab, such as the Molecular Foundry, Advanced Light Source, and National Energy Research Scientific Computing Center (NERSC), play key roles in facilitating innovations in our research.

Q. These systems are far offshore, making them challenging to access for maintenance. How can technology help track and predict their performance when people aren’t nearby to monitor operations?

Wu: Digital twins are representations of structures made using advanced computer modeling, often jointly with real-time monitoring data, that scientists can use to control, simulate, and monitor how the FOSW system would respond to different weather or marine conditions.

For example, we can simulate conditions of a hurricane and see exactly how the system would function under this extreme weather – right from our desktop computers.

With real-time data feeding into the digital twins, system response to actual “on-the-water” field conditions can be monitored to support decision-making, for example when to send a crew to conduct system inspection. This could significantly reduce costs by avoiding unnecessary trips, and by allowing proactive maintenance of the system before larger, expensive failures.

Last summer, our team used shake table testing of an actual turbine at the Pacific Earthquake Engineering Research Center at UC Berkeley’s Richmond Field Station, to test the ability of the fiber optic sensing to monitor how the turbines would respond to wave movements far offshore.

The shake test helps evaluate and optimize deployment of sensors which eventually will be sitting on structures in the middle of the ocean and autonomously communicating data to land via fiber cables.

Q. How important is collaboration to reducing the cost of floating offshore wind?

Wu: DOE’s floating offshore wind earthshot has an ambitious goal of 70% cost reduction by 2035. This requires a system-level approach that optimizes all steps through the entire lifecycle of FOSW from material design, structural construction, deployment, operation, and maintenance.

Partnering with institutions and industries with different expertise allows us to efficiently develop these new and complex technologies that can help shift the nation’s energy economy to one built on clean, renewable sources.