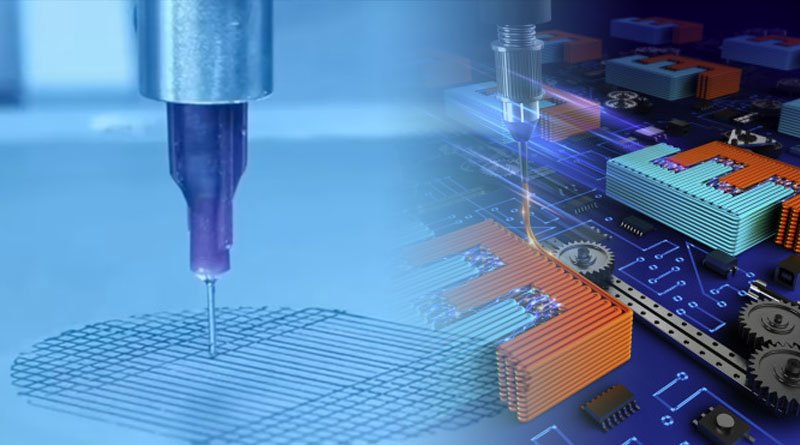

A Chinese startup focused on making batteries using 3D printers has developed a battery-making technology using its own 3D printers and 3D printing technology.

A Chinese startup focused on making batteries using 3D printers has developed a battery-making technology using its own 3D printers and 3D printing technology. Founded in 2021, TOP. E is already profitable. It has partnered with carmakers FAW and Aiways as well as with the Dalian Institute of Chemical Physics, Chinese Academy of Sciences.

Now the company says it can make 3D electrodes that are two or three times thicker than those made with traditional coating technology.

Its 3D-printed electrodes can radiate heat more efficiently than conventionally made electrodes, TOP.E says. They also have fewer self-ignition risks, the company says. As they can help reduce the energy consumption of current collectors, separators and ancillary materials, overall manufacturing costs would be about 30% lower, TOP.E says.

Capital spending on production lines could be 40% lower than the previous process under the same conditions, it says. Energy density can also be improved.

There are currently five or six processes involved in making electrodes, such as coating, pressing, cutting and winding, a TOP.E executive said. The overall process is thus energy intensive and requires that electrode factories be located on large sites.

There are other drawbacks to conventional electrode plants such as large initial investments and the need to solve safety, cost and other problems.

3D printing technology solves these problems. It is also more advanced, safer and less expensive than previous technologies, TOP.E says. In addition, 3D printers can be more freely tailored for precise purposes such as ultra small batteries, special batteries and custom-made batteries.

3D printing technology also lends itself to making solid-state batteries, another TOP.E focus. These batteries are considered promising candidates for next-generation batteries.

The company has established a 3D printing technology that makes use of multiple electrode materials. In addition, it has successfully created efficient multi-head 3D printers that are compatible with any kind of electrode material available in a given market.

The printers can also be used to design and make solid-state batteries, the company said.

With the value of China’s battery market having grown to nearly 1 trillion yuan ($147.3 billion), industry players are striving to come up with new technologies and materials that go beyond conventional coating and liquid lithium-ion systems.

36Kr, a Chinese tech news portal founded in Beijing in 2010, has more than 150 million readers worldwide. Nikkei has partnered with 36Kr since 2019.

Originally published at Nikkei Asia