A Paper-Like Layer Made From Sunflower Pollen, And A Layer Of Styrene Acrylate Copolymer Is Found In Laser Toners And Other Edible Inks.

Combining sunflower pollen with printer toner, scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a paper-like material that is able to fold itself into new shapes in response to environmental humidity. Patterns digitally printed on the pollen paper using a commercial laser printer, determine the three-dimensional shape the paper folds into. The process is reversible but can be “frozen” if a layer of chitosan (a natural sugar found in shellfish) is applied onto the structure. The NTU Singapore team demonstrated their method, by creating several geometrical configurations, from straws and boxes to more complex forms like a 3D paper orchid, and reported it in a paper published in the peer-reviewed journal Proceedings of the National Academy of Sciences of the United States of America (PNAS) on 19 Oct.

The printed pollen paper’s ability to fold into 3D configurations demonstrates its potential for use in ‘intelligent’ green products such as self-folding envelopes, boxes, and food containers, said the study’s senior corresponding authors, NTU President Professor Subra Suresh and Professor Cho Nam-Joon from NTU’s School of Materials Science and Engineering. Other co-authors of this all-NTU research team include Assistant Professor Huang Changjin of the School of Mechanical and Aerospace Engineering and School of Chemical and Biomedical Engineering, along with post-doctoral fellows and students: Ze Zhao (lead author), Jatin Kumar, Youngkyu Hwang, Jingyu Deng, and Mohammed Shahrudin Bin Ibrahim.

The material also has the potential to be used in ‘origami robots’ – flat sheets that can fold autonomously into 3D shapes – for electronic and biomedical applications with special shape requirements, shape-dependent tissue engineering, and stimuli-triggered drug delivery. NTU Distinguished University Professor Subra Suresh said: “Building on our earlier studies on the unique properties of pollen, we combined easy-to-process pollen grains and cost-effective digital printing to develop a moisture-sensitive biomaterial-based system that can morph on demand into geometrical configurations that lead to complex shapes depending on the patterns we print.

“Through computational simulations, we also modelled and predicted transformations of the material using various printed patterns and in response to various levels of humidity. This helped us to develop a general framework for materials and geometry design to produce highly controllable shape-morphing natural materials in a scalable and sustainable manner.”

Professor Cho Nam-Joon said: “In this work, we demonstrated how economical and eco-friendly plant-based materials and readily available printing technologies could be utilised to produce autonomous, on-demand deformation and designing complex shapes. By automating the folding process through controlling environmental humidity, origami-inspired machines can be produced without manual folding, reducing the skill and time necessary for fabrication.” The NTU research team has filed a patent application for potential commercialisation of the technology. This use of natural renewable resources to develop new-generation eco-friendly materials is in line with the NTU 2025 vision and the NTU Sustainability Manifesto, which aspires to develop sustainable solutions to address some of humanity’s pressing grand challenges.

Inspired by origami in nature

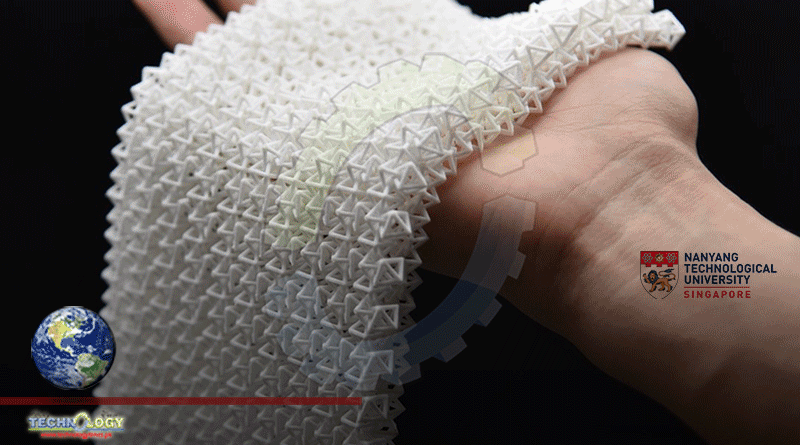

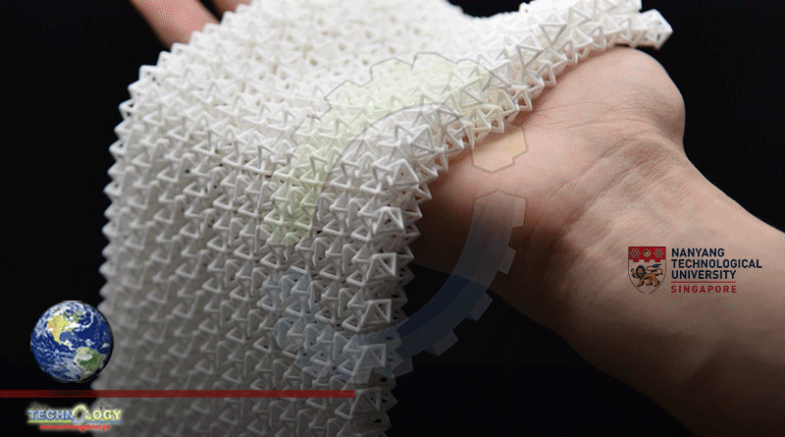

The self-folding pollen material is the NTU team’s take on origami fabrication, an important design principle found in nature, that describes, for example, how flowers are folded within the bud. The scientists were inspired by the geranium seed’s ability to coil up and straighten, depending on humidity levels (amount of water vapour in the air). The NTU material has two layers: a paper-like layer made from sunflower pollen, and a layer of styrene acrylate copolymer that is found in laser toners and other edible inks. The copolymer layer is hydrophobic – it repels water. While the scientists opted for toners used in commercial laser printers for this study, they have shown in previous studies that edible inks could also be printed onto the pollen layer using standard digital printers.

The process of making the pollen-based paper layer involves turning tough pollen grains into soft microgels through a technique similar to simple soapmaking. Through earlier studies, the NTU team showed that this pollen-based paper, which does not cause allergic reactions, is capable of ‘moving’ autonomously in response to changes in humidity[1]. The result is a bilayer material that folds and bends reversibly due to the mismatch in volume change, caused by variations in humidity, between the pollen paper and the parts printed with hydrophobic toner. The scientists found that the geometric orientation of the printed pattern influenced the direction and degree of coiling and folding. For instance, a 3 cm x 0.5 cm piece of pollen-based material with stripes printed at a 60° slant coiled up to form a straw. However, similar pattens when printed with vertical stripes, would roll up to form a circle. Varying the printing patterns led to more complex forms, as demonstrated by the scientists who reproduced the complex structure of an orchid using this method.

The NTU team also found that the length of the printed pattern affected the angle at which the pollen-based material would fold, allowing them to create a box and a pyramid which could open or close when triggered by changes in humidity levels. “The flexibility of this design and printing strategy to produce box-like structures also illustrates pathways to convenient digital manufacturing of containers (such as boxes, cups, and bowls) made of natural materials that are economical, environmentally friendly and amenable to large-volume production,” said Prof Cho. Computational simulations of the material’s behaviour revealed a direct link between the amount of coiling in the material and the stress caused by the strain mismatch between the pollen substrate layer and the patterned layer, under varying levels of humidity.

‘Freezing’ the autonomous shape change

For applications that might require the material to remain in a folded or coiled state despite changing humidity levels – for instance, a food container or a box transported in humid weather – the material’s reversible and autonomous shape change can be switched off with a coating of chitosan, a natural sugar that is found in the shell of crustaceans. In lab studies, the NTU scientists showed that pollen paper treated with chitosan did not morph in response to changes in humidity. This suggests that the structures fabricated from the pollen-based material could be “frozen” into their new shape when coated with a layer of chitosan, said the scientists. The team is now looking at increasing the sensitivity and speed of the pollen material’s response to moisture and refining the material’s stability and controllability.

This news was originally published at Eurek Alert