CNC Machine Have Become Quite Popular Over The Past Several Years Because They Can Precisely Control A Large Number Of Pieces.

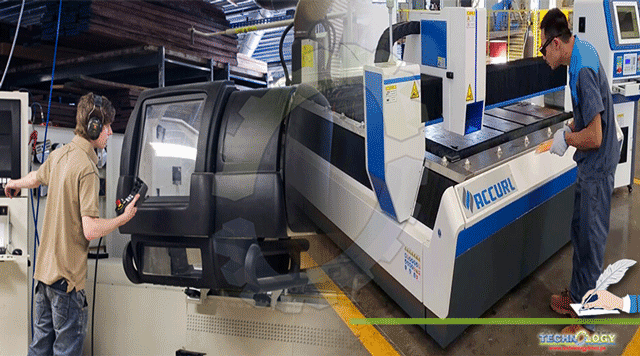

CNC (Computer Numeric Control) machining is an intricate production process that employs pre-programmed software to run factory equipment and other factory machinery. CNC Machine Have Become Quite Popular Over The Past Several Years Because They Can Precisely Control A Large Number Of Pieces, as well as offering consistent quality throughout the entire run. Many companies now use CNC machinery to build everything from prototype aircraft to furniture. In fact, CNC has even started using computers to control the operation of CNC machinery.

CNC Routers

For manufacturing parts, we usually use CNC Routers. These routers are basically an important type of CNC machine that has its own CNC computer – much like your computer on your desktop. The router directs the machine and programs the cut places at which the router will perform its operations. Some routers are able to program and record many cuts in a single program, while others are limited to a single cut.

CNC Milling Machines

Another type of CNC machine is the CNC milling machine. A CNC milling machine has its own CNC computer and programs the woodcut positions. The CNC milling machine may also incorporate a program for building larger models. Some CNC lathes are capable of building prototypes. A CNC lathe is not the same as a CNC router or CNC milling machine.

Important Milling Machines:

Some important milling Machines are given below:

- 6-axis milling machine.

- Plain milling.

- Face milling.

- Chamfer milling.

- Form milling.

- Profile milling.

- Gear milling.

These machines can be programmed in various ways. For example, there are many programs available that enable routers to communicate with software packages to map out the precise cut. The best part about CNC machinery is that the programs use sophisticated mathematical equations to allow the machine to repeat the operation over. Some types of CNC routers, such as AutoCAD, have built-in programming capability. This feature makes it easy for anyone to create and program a CNC router to meet a customer’s specifications.

CNC Machine Technologies

There are different processes available for CNC machine operation. Some types of CNC machines use Direct CNC (DCN) technology to transfer designs directly into CNC machine parts. CNC machines that operate with this technology can produce prototypes of any possible design at high speed and precision. This is important for industries that require production to be done as per their strict deadlines.

CNC milling machines are capable of cutting different types of metal. It is no longer necessary to run out and purchase metal sheets from a manufacturer. Metal can be directly CNC machined with a CNC machine. Many industries, such as automotive and metal fabrication, use this technology to manufacture parts and components.

CNC Milling Machine Applications

These machines are also used in a variety of metal cutting processes. Some of these types of CNC machines include drilling, piercing, sawing, routing, beveling, etc. It is very important to understand the types of CNC machines that are available so that you will know what is available and what is required to execute the task.

With the advancements in computer numerical controlled (CNC) technology, manufacturers can design and manufacture virtually any type of product they want. CNC machining offers designers a wide variety of options for designing parts or components. If you want to find the ideal machine for your particular project, consult a manufacturer that specializes in CNC machine systems.

What is G-Code:

CNC milling machines use g-code, which is a sequence of numbers that specify the size, pitch, and diameter of each cut. A CNC machine operates with software that controls the operation of CNC machines by interpreting the g-code. There are several types of CNC machines and each has different functions. The most common types of CNC machines include direct drive machines, line machines, rotary machines, lathes, and grinders. The most common types of CNC milling machines are rotary grinders, inline grinders, tabletop grinders, and milling machines.

CNC Machines VS Manual machines

CNC machines have become extremely popular over the years because they offer greater accuracy than manual machines and are much less expensive to operate. CNC milling machines provide users with both precision and speed. CNC milling machines can make both low-volume and high-volume production cuts. CNC machines allow for customization of cut pieces and can create cuts in a matter of minutes. Because these machines can virtually perform any operation with just a single command, it is much more efficient than a human being.

The types of CNC machines can vary widely. For instance, a CNC milling machine may use a variety of different types of CNC program languages to control the operations of the machine. Some types of CNC programs use predictable programming, which makes them more repeatable; while other types of programs use imperative programming, which allows for more customizable results. Different types of CNC programs are designed for different purposes and different types of machinery. There are many types of CNC machines available for different purposes and applications.