Nanofluids have attracted attention in a broad range of engineering implementations due to their great properties, which may be used to effectively cool devices while also improving energy efficiency.

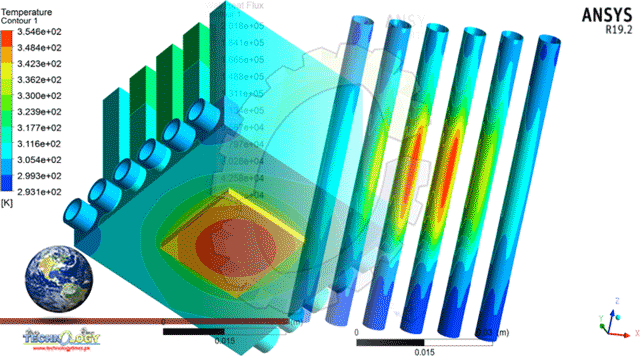

Electronics devices growth in the last decade of the twentieth century ushered in a revolution inside the electronics segment. Continuous micro-sizes and operation cause these devices to heat up, resulting in a reduction in their performance or damage to their parts. Because heat can decrease device performance and life span while also wasting energy, offering an incorporated and effective cooling system has become a significant part of the design of device equipment. One of the key challenges of modern generation technology is the cooling of electronic devices. Nanofluids have attracted attention in a broad range of engineering implementations due to their great properties, which may be used to effectively cool devices while also improving energy efficiency. In view of the above defects, this numerical research object to examine the chip surface temperature, heat transfer rate, thermal resistance, Darcy friction factor and reliability of microelectronic chips in minichannel heat sinks is scrutinized by utilizing a TiO2/water nanofluid as a coolant and comparing the nanoliquid outcomes with the outcomes of water. TiO2/Water nanofluids at 1%, 2% and 3% volume concentrations are employed for this scrutinization. Here, a commercial CFD ANSYS (R19.2) FLUENT software package is used to analyze the electronic chip performance. The CFD ANSYS (R19.2) FLUENT software package is used for modeling, meshing and simulation of the current study.

Introduction

Currently, modern electronic machinery generates strong heat fluxes. As a result, advanced electronic machinery, such as integrated circuits, electronic chips and computer microprocessors, demands large thermal dissipation rates for cooling. Heat sinks are technologies to remove heat generated from electronic processors with the help of the energy difference between the warming surface and the coolant. The objectives of using heat sinks are divided into two categories: (I) to improve the rate of heat dissipation to improve the efficiency of electronic devices and (II) to increase the electrical package dependability and performance. It is generally acknowledged that electronic chip malfunction and excessive energy consumption are caused by shrinking electronic component dimensions, which drastically boosts heat flux per unit area, resulting in heat difficulties and deterioration in chip efficiency and reliability. One of the most difficult problems in the creation of next-generation circuit boards, microprocessors, and other tiny integrated memory chips is addressing these challenges. Several kinds of heat exchangers and cooling processes are currently used in electrical cooling. Electronic cooling can be accomplished using a variety of approaches, including jet impingement cooling, pool boiling, two-phase flow in microchannels, spray cooling, and heat pipes. In the past, air-based cooling methods were widely used. However, due to the poor thermal transportation properties of air, they have some drawbacks1,2. Water-based strategies were later used to overcome the drawbacks of the air cooling process. According to many researchers, the thermal efficiency of water-based systems is significantly better than that of air-based systems. However, because of the latest developments in micro- and nanoscale heat transfer components, the heat efficiency of water-based systems may be limited in their ability to eliminate large heat fluxes from advanced electronic devices. Li3 proposed a nanofluid flow through microchannel. Paisarn and Lursukd4 examined the heat sink impact on minirectangular fins to improve the thermal performance through nanofluids. The output demonstrated that the thermal efficiency rate for nanoliquids is greater than that for deionized water. Farsad et al.5 scrutinized the numerical computations of microchannel heat sinks utilizing nanofluids and found that the microchannel heat sink cooling performance was better than that of pure water in minichannel heat sinks. Saadoon et al.6 explored the thermal transportation of nanofluids in minichannel heat sinks.

Although common working fluids have poor thermal characteristics, it appears that using fluids with improved heat characteristics rather than ordinary fluids is required7,8. Solids, on average, have stronger heat conductivities than base liquids8. Therefore, it appears that scattering solid particles in host fluid may improve the heat proficiency of host fluid9,10. Tiny-sized particles are unstable and sediment, whereas Choi11 demonstrated that tiny-sized particles disperse faster than micron-sized particles. These nanofluid suspensions have greater heat conductivities than the base liquid12. Muhammad et al.13 investigated the numerical computations of Eyring-Powell nanofluids over three-dimensional surfaces with Arrhenius activation energy. Sheikholeslami et al.14 examined the thermal performance impacts on copper/water nanoliquids by adopting CVFEM. Wakif et al.15 investigated magneto nanofluid flow through horizontal layers. Khan et al.16 discussed the behavior of Casson blood base nanofluid flow through a rotating disk.

In various areas, nanofluids with high heat efficiency have been commonly utilized rather than conventional media (such as water and oil) to fulfill the demand of high-performance heat transfer media. Currently, nanoliquids have been recommended by the majority of researchers in the field of solar energy. Yu et al.17 suggested that CuO/Ag nanoliquids with a volume of 0.025 percent have the best photothermal renovation capacity. This helps to improve the transfer of energy between light and heat in the solar heat collector packed with nanoliquids. Moghadam et al.18 discussed copper oxide/water nanofluid flow through plates inside a solar collector.

Computational fluid dynamics (CFD) approaches are strong tools for simulating fluid flow and associated heat and solutal transport by computing a numerically mathematical system that governs these processes, taking use of rapid and ongoing advances in computers and computing methodologies. Extensive comprehensive examination, fundamental investigations of redesign and new systems, in-depth product research & innovation, and troubleshooting are all areas where CFD simulations are useful19. In comparison to analytical and experimental fluid dynamics, CFD is highly significant in computations of microelectromechanical system (MEMS) technologies, particularly in the design of effective microchannel heat sinks. Adopting CFD modeling tools in invention and design saves time and cost when compared to experimental techniques. Klazly and Bognár20 analyzed the CFD computations of nanofluid flow influenced by flat plates. Mohammed et al.21 used a rectangular tube to analyze nanofluids. Naphon and Nakharintr22 examined the numerical computations of nanofluids in microchannel heat sinks.

The fast demand for electronic equipment necessitates the development of small advanced cooling technology that can deliver higher performance and reliability. Electronic equipment faces challenges such as excessive power consumption and short life. Many electronic cooling strategies are being introduced by researchers. One of them is a desire to learn more about electronics cooling. Many scientists have scrutinized the significance of several nanofluid combinations on the cooling performance of electrical devices. The advent of current technology has resulted in a reduction in the dimensions of industrial equipment in recent years. However, adequate cooling and energy removal is a major issue in utilizing such equipment, especially in electronic systems. As a result, improving the thermal efficiency of systems has become extremely important. Based on the abovementioned survey of the literature, a few analyses have focused on circular microchannel heat sinks with fins by utilizing water-based suspensions with TiO2 nanoparticle applications for heat transfer in electronic chips. Therefore, to fill this gap of investigation, we tried to improve the cooling proficiency of electronic chips in regular six-channel heat sinks by using a TiO2/water nanofluid utilizing the numerical finite volume method. The main purposes are mainly as follows:

The impacts of the heat transfer rate, Nusselt number, Darcy friction factor, thermal resistance and reliability of the electronic chip on the microchannel heat flux are scrutinized.

The effects of the surface temperature of the chip and TiO2/water nanofluid behavior as a coolant are investigated.

Here, the cooling efficiency of nanofluid ϕ=1%,ϕ=2%,ϕ=3% in a microchannel heat sink is scrutinized numerically by utilizing CFD ANSYS-Fluent.

The modeling, meshing and simulation are explored by using computational CFD ANSYS-FLUENT (R19.2).

The flow governing system of equations is approached numerically by adopting the finite volume method (FEM) in ANSYS-FLUENT (R19.2).

Mesh specifications/generation

Mesh independence study

Throughout the mesh independence study, three different cases were carried out: (I) coarse, (II) normal and (III) fine. After the analysis, we found a fine mesh to be given accurate results and of good quality. The mesh characteristics are reported in Table 1. Eight dissimilar grids were utilized to confirm that outcomes were not dependent on the grid. The Nusselt number and Heat transfer outcomes (depicts in Table 2) are utilized as the indicators of the outcomes. Due to diverse outcomes, the fifth grid was preferred as final grid. Reasons for choosing a fifth grid are summarized below:

Better and smoother solution convergence at good criteria.

Much better accuracy.

Structured multi zone mixed cells mesh along with much better quality as compared to other meshes.

Feasible Results in relatively less computational time.

For current simulation purposes, a machine with the following specification is utilized:

1.

Ram: 12 GB.

2.

Processor: Intel core i5.

3.

Time: 30 min iteration 100.

4.

Convergence at 100 iteration.

Meshing of the microchannel with a heat sink was performed with the help of a commercial ANSYS-FLUENT (R19.2) tool. Figure 1 shows the mesh of the microchannel heat sink in cases of skewness, element quality and mash of six microchannels.

Methodology

Problem description

CFD modeling is now a well-established practice for computing complex issues in various modern engineering sectors because it is convenient. Here, the three-dimensional laminar flow of steady state from the laws of conservation of mass, momentum and energy is taken into account. A physical view of the problem under a heat sink with a microchannel is displayed in Figs. 2 and 3. According to the figure, six microchannels and five fins are installed with a chip to increase the cooling proficiency. The microchannel dimensions are width = 55 mm, length = 55 mm and height = 42 mm, as mentioned in Table 3. The microchannel in the heat sink and identical cross section of channels are shown in Fig. 4. To approximate the heat generation in the electronic chip, a uniform heat flux (q′′=70W/cm2) is employed on the base wall surface of the channel heat sink. In this article, TiO2 nanoparticles with a diameter of 35 mm were dispersed in water as a coolant. The computational package Fluent, which uses the finite volume method, is a popular program for computing fluid flows. Figure 5 are drawn for mash of microchannel heat sink in three different view (i) side view and five fins (ii) bottom view (iii) microchannel heat sink by utilizing ANSYS (i.e., CFD FLUENT) computational software.

This news was originally published by Nature.