Biowaste is generated in various forms (from forest residue, the agricultural and food industry and municipal waste) and is increasing daily, creating a problem for managing and disposing of it.

Nearly one-third of food produced is lost from the food chain as waste, resulting in economic loss and posing a threat to the environment. The use of waste to produce energy and recover other nutrients not only improves the economic conditions of a country but also aids the sustainable development of human society.The current use of fossil fuels and the impact of greenhouse gases on the environment are driving research into renewable energy production from bio-waste. Nearly 1.3 billion tons of municipal solid waste is collected worldwide; this is expected to increase to 2.2 billion tons by 2025.Treating this biowaste with various biowaste to bioenergy (BtB) technologies is a viable approach to both treating waste and generating energy.

Biowaste sources

Biowaste is made up mostly of biomass and can thus decompose under aerobic and anaerobic conditions. Managing biowaste in a cost-effective manner is very important to protect the environment and improve standards of living. Therefore, integrating it with energy producing technologies may help to solve energy and waste management problems while also generating revenue. Biowastes can be classified according to their origin and different strategies are required for their pretreatment and conversion into bioenergy.

Food processing waste

There has been a rapid growth in food processing industries, grocery stores, and restaurants to meet the food demanded by increasing populations. Meanwhile, progress in the development of waste management strategies has been slow, resulting in an accumulation of various food wastes. The food industry includes meat processing, breweries, vegetable oil manufacturing, and confectionary. Food industry waste can be solid or liquid. Solid waste includes fruits that d Liquid waste is produced when fruits, vegetables, and meat are washed and consist of starch, sugar, and solid organic matter. Edible oils used to fry food is disposed of after only a few uses. Annually, more than 12 million tons/year of WCO is produced, and this is expected to increase to 18 million tons/year by 2020.

Paper industry waste

The pulp and paper industry is considered the third largest polluter. Pulping is a process that breaks the bonds in the structure of wood. The paper industry uses various mechanical and chemical methods (alkaline: sulfate or Kraft; acidic: sulfite) to convert wood into pulp. The quality and yield of the pulp produced depends on the pulping method used. Approximately 40–50 kg of sludge is generated during the production of 1 ton of paper. Managing these industrial wastes, which are rich in organic content and will result in odor issues and pose a threat to aquatic and terrestrial ecosystems if discarded openly, is also a problem. These wastes can be applied directly in the AD process or other technological waste-to-energy processes for energy production.

Other Biowaste Sources

Forest and wood processing industry

Forest and agriculture waste Milling

Municipal solid waste Animal waste

Bio-based technologies in Biowaste to Bioenergy

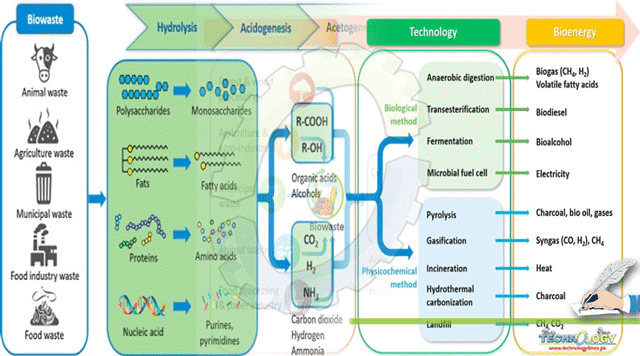

Biowaste is enriched in organic components and can be used to produce bioenergy. Different biological methods (such as anaerobic digestion, transesterification, fermentation, and microbial fuel cells) and physicochemical methods (including incineration, gasification, landfill, and pyrolysis) have been applied to produce different types of bioenergy (biogas, biodiesel, and bioelectricity).

Biogas from waste

Anaerobic digestion (AD) is the collective process of the breakdown of biological material carried out by a group of microorganisms in the absence of oxygen. This process is used in the maintenance of biological waste and to produce biogas that is composed mainly of methane, carbon dioxide, and trace amounts of other gases. AD is a stepwise process and occurs via hydrolysis, acidogenesis, acetogenesis, and methanation carried out by various groups of microorganisms. Biomass is composed of a complex polymeric material; during hydrolysis, microbes produce hydrolases that convert it into simpler molecules (sugars, amino acids, and fatty acids).

Biodiesel from Biowaste

Biodiesel is a biofuel produced from vegetable oil, animal fat, or microbial oil (produced by fermentation using biowaste as a carbon source) via transesterification with various alcohols. It can be used to power an engine directly, in pure form (B100) or mixed with petro diesel at different proportions to produce different grades of fuel, i.e., B20 (20% biodiesel:80% petrodiesel), B5 (5% biodiesel:95% petrodiesel), and B2 (2% biodiesel:98% petrodiesel).

Biodiesel from animal fat waste (AFW)

AFW is generally TAG composed of glycerol and three long-chain fatty acids. These fats cannot be used directly as fuel to power engines because of their high viscosity. AFW originate from meat processing, the leather industry, and slaughterhouses, and contains free fatty acids that affect the transesterification process; this makes pretreatment a necessary step. Extracted fat can be further subjected to transesterification processes to produce biodiesel in a similar manner as fat from other feed stocks. Successful biodiesel production from different animal fats (beef tallow; pork lard; chicken, fish and sheep) have been reported by different research groups.