New research shows that a molybdenum disulphide catalyst is more selective and works at lower temperatures in transformation of CO2.

Molybdenum disulphide offers a more sustainable transformation of CO2.

Chemists have suggested a new method for turning carbon dioxide into methanol using a special catalyst – a technique that could be useful in reducing atmospheric carbon dioxide, transforming it for further use.

Carbon capture and storage could be achieved using carbon dioxide and hydrogen to make methanol, which can be used commercially.

Previously, this required high temperatures, and generated harmful by-products.

New research shows that a molybdenum disulphide catalyst is more selective and works at lower temperatures.

Carbon dioxide (CO2) can be combined with hydrogen (H2) to produce methanol (CH3OH), which, as a liquid, can be easily stored and has other commercial uses.

Hydrogen can be made and sourced renewably, but it’s difficult to turn hydrogen and carbon dioxide into methanol, because carbon dioxide is a very stable molecule and resists change. It requires specific conditions and some sort of catalyst to encourage the reaction.

Commercial metal-oxide catalysts are inefficient and energy intensive, needing temperatures above 300°C , and they make a lot of carbon monoxide (CO) as a by-product. Recent research has suggested that transition-metal catalysts could be added to the reaction to lower the temperature required, but this then makes a lot of methane (CH4) as well.

Now a paper published in Nature Catalysis has found an alternative route, suggesting a new substance that could work as a catalyst.

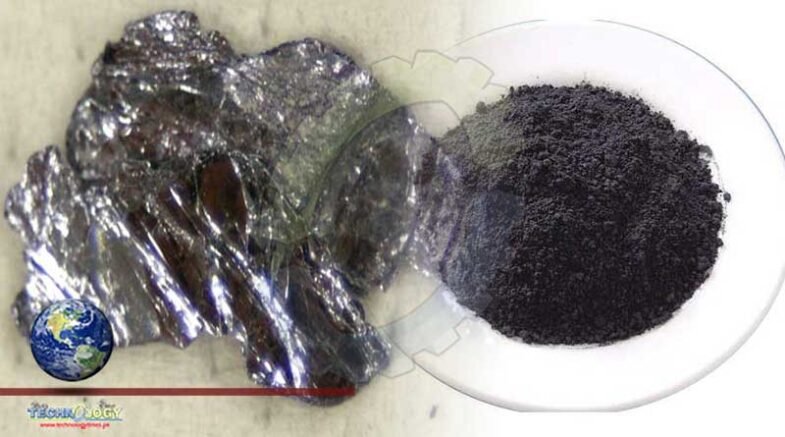

The researchers, based at the Dalian Institute of Chemical Physics of the Chinese Academy of Sciences, tested a molybdenum disulphide, or MoS2, compound. The MoS2 they tested was ‘sulphur vacancy-rich’ – meaning there was slightly less sulphur than normal in the compound, leaving atom-sized gaps in its surface.

They found that these gaps could catalyse the production of methanol, forming active sites for the carbon dioxide and hydrogen to react. This made the reaction much more selective, with more methanol formed and fewer by-products like carbon monoxide or methane.

The reaction also works at much lower temperatures than the traditional 300°C. In fact, the reaction works at room temperature, but was most effective at 180°C, when it was more selective than any other known commercial or experimental catalysts.

The catalyst also worked for a long time. The researchers found that the molybdenum disulphide could convert CO2 into methanol for over 3000 hours without a drop in selectivity or efficiency.

Dehui Deng, a professor at the Dalian Institute of Chemical Physics and lead researcher on the team, says that the work “provides a novel strategy for the development of new catalysts to be used in CO2 hydrogenation”.

Originally published at COSMOS