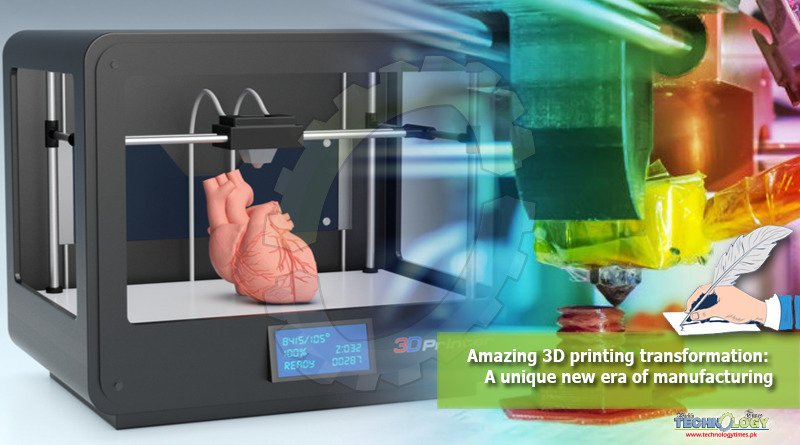

All over the world, 3D printing transformation is getting place to change our lives, and disrupt how we make and trade everything from boats to hearing aids, from electric cars to medical equipment.

As 3D printing (3DP) replaces traditional processes, manufacturing will change dramatically. 3D products can be in-situ where they’re consumed, impacting trade volumes.

3D printing can print complex structures, reducing the number of parts needed, and also shortens supply chains.

In Mexico, a startup is 3DP an entire neighborhood to build 50 homes for area’s poorer of the poor families. Just as little as 24 hours’ time, they printed two earth quack-resistant homes, ready for living.

Around the globe, charities are using 3DP to rebuild areas after natural disasters. Printed shelters in Haiti and El Salvador are prime example, where people are living safely and happily.

But it is not just homes… As per World Bank report, hearing aids are increasingly 3D printed. And since 3DP began to dominate hearing aid production, trade volumes of hearing aids have increased by 58 per cent.

Scientists are also learning about how to print human tissue similar to cartilage, which could be implanted into arthritic joints where cartilage has been destroyed.

The printer uses bio-inks, which contain living cells and can be used for 3DP of complex tissue models. These bio-inks can replicate an extra-cellular matrix environment to assist the adhesion, propagation, and variation of living cells.

The bio-inks are mixed with hydrogel and polyester fibers to become tough enough for printing. This process will help to reduce the pain of millions of patients, specially over the age of 65 years, who suffered arthritis.

In Maine, United States, academicians printed the world’s largest 3DP boat which is a prototype of a military patrol boat. The size is 7.62 meters long and weighs 2.2 tons. It took just 72 hours to print from a blend of wood cellulose and plastic. This could herald a low-cost, sustainable alternative for boatbuilding.

One another ease of 3DP is the portability of 3D data files, that can be copied and shared easily. But, at the same time, it is problem as well, as it will increase piracy and affect intellectual copyrights.

3DP can also save materials compared with traditional manufacturing. But it could generate more plastic waste, as unsuitable 3D printed objects are thrown away. Scientists are working to make 3DP more accurate to reduce plastic waste.

in 2018, 3D printing transformation revenues were less than 0.1 per cent of all manufacturing revenues. But they have seen 27 per cent annual average growth for the last 30 years.

Governments and companies are needed to advance 3DP by helping people to get 3DP skills with training schemes; work out where 3DP could improve supply chains; and develop regulations so that 3DP became secure, accessible and environment friendly.